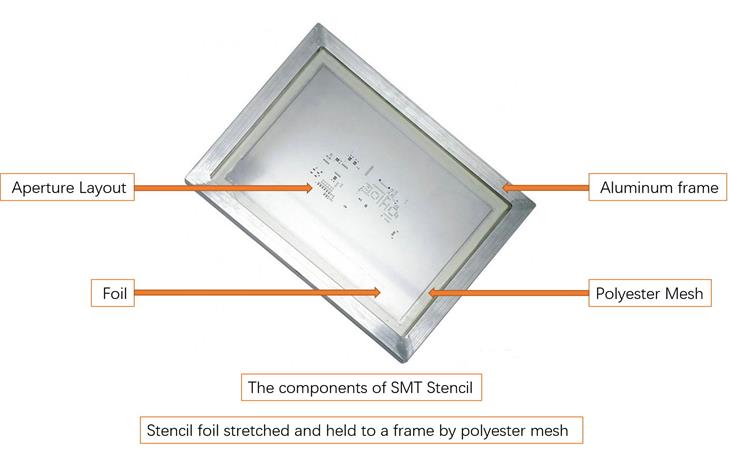

PCB Stencil is made of stainless steel sheets by laser cutting process. It is instrumental for SMT or surface-mount technology PCB assembly, especially in component placement. PCB stencils make solder paste printing easier, faster, and more precise by ensuring that every pad receives a suitable quantity.

The PCB stencil serves two primary functions.

The first is to ensure the precise placement of a material on a substrate, such as a solder paste, flux, or encapsulant.

The second is to provide the formation of appropriately sized and shaped deposits.

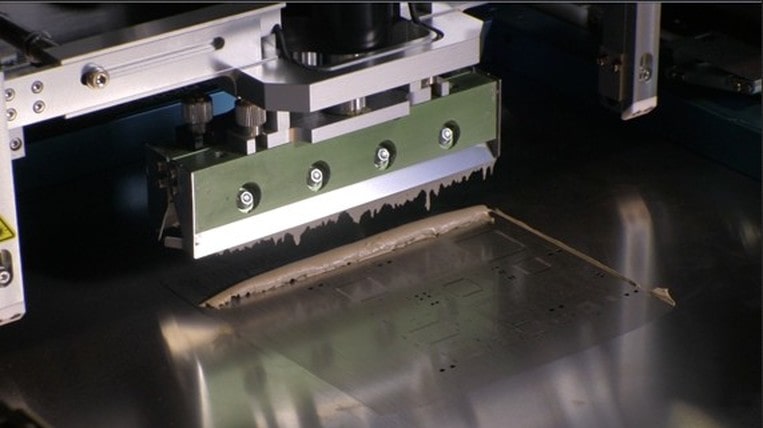

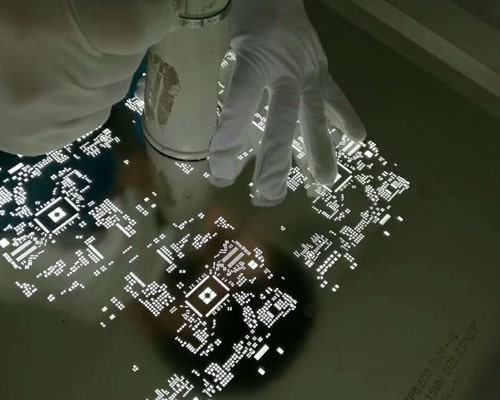

Squeegee solder paste through the stencil.

The stencil ensures the solder paste is in the right amount in the correct position.

Then you can place surface mount components on solder paste and put it into a reflow oven.

1. When the solder paste is not opened, it should be stored in a constant temperature and humidity freezer;

2. The temperature of solder paste needs to be consistent with room temperature before use;

3. The solder paste needs to be stirred before use, and the stirring time is about 3-5 minutes.

1. The temperature and humidity requirements of the solder paste in the printing machine: 25±3℃, RH 40~70%;

2. Scraper pressure: the edge of the solder joint is clear, the surface is flat, and the thickness is appropriate;

3. Scraper speed: ensure that the solder paste is rolling rather than sliding relative to the squeegee. In general, 10-20mm/s is appropriate.

1. Reflow soldering can process surface-mounted circuit boards. The process is complicated and can be divided into single-sided PCB Assembly and double-sided PCB Assembly.

2. The reflow oven has at least 3 temperature zones: preheating, soldering, and cooling.

3. The difference between wave soldering and reflow soldering is that wave soldering is mainly used for soldering plug-ins; reflow soldering is used mainly for soldering SMD components.

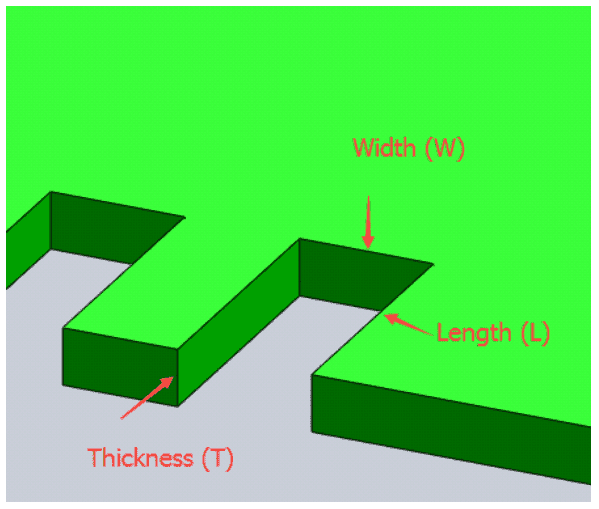

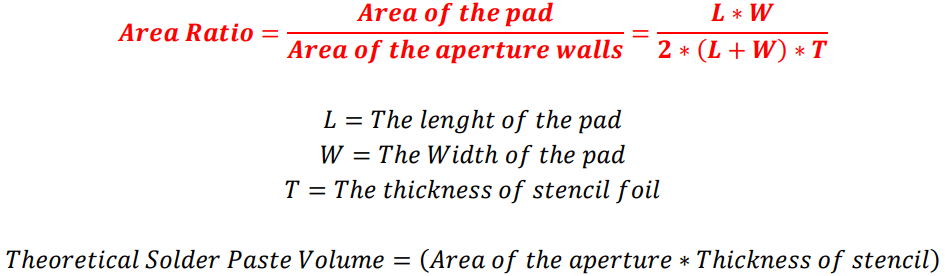

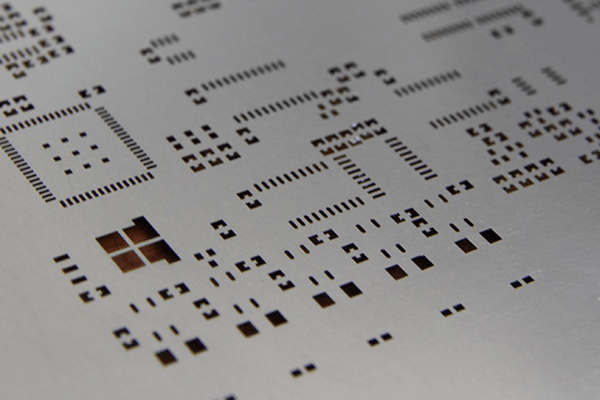

When developing and ordering a PCB stencil, it is necessary to understand the importance of the thickness of the stainless steel sheet to obtain satisfactory product quality. At the same time, it is also required to know the calculation formula of the thickness of the PCB stencil.

The thickness of the stainless steel sheet: The exact thickness of the stencil sheet ensures that the required amount of solder paste is released through the opening.

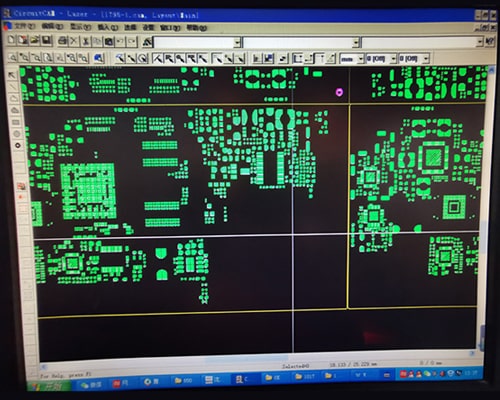

SMT Stencil manufacturers accept the following three data formats that can be used for stencil production:

Generally, SMT stencil manufacturers require the information provided by customers to include the following PCB layers:

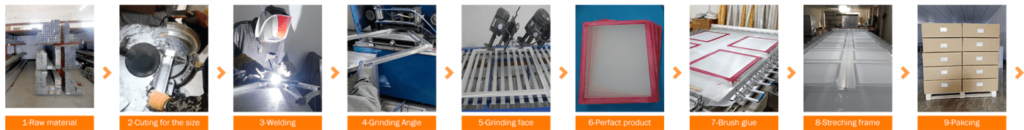

All of our SMT Stencils stencils are 100% laser-cut type 304 full-hard stainless steel, ensuring the finest quality finish on the market today. We use a .001″ laser beam with 98% overlap creating an extremely smooth hole that provides the best paste release. Most stencil fabricators use a .003″ laser leaving mouse bites on the aperture edge. You can choose a PCB Prototype stencil, a frameless foil stencil, or a rigid permanently mounted stencil. Both the frameless and framed stencils come in various sizes to accommodate your printer and stencil requirements.

Aluminum PCB is one type of metal core PCB that using aluminum substrate. With their layered design using a copper foil, these PCBs offer superior Cost performance.

Your Quote will be replied in 24Hours, from the email with the suffix “@Halosemi.com”.