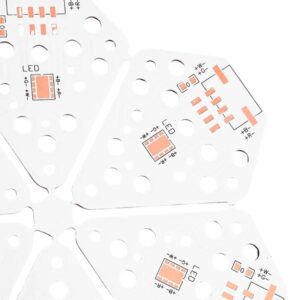

Copper core circuit boards are a type of metal core PCB. With their layered design using a copper base, these PCBs offer superior thermal conductivity.

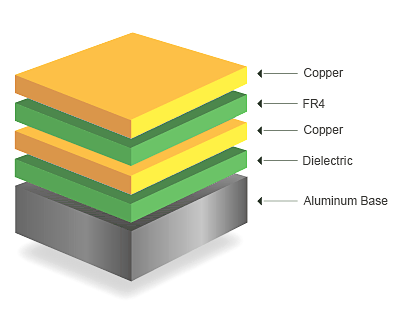

The base layer is made of a copper substrate that offers high thermal conductivity and heat transfer.

Copper core PCBs use prepreg or another high thermal conductivity insulation to improve heat transfer.

Copper foil makes up the circuit layer, and these often range from 1 to 10 ounces.

An added dielectric layer absorbs the heat that travels through the circuit layer and sends it to the copper substrate for dispersion.

Copper core circuit boards are a type of metal core PCB that using copper substrate. With their layered design using a copper base, these PCBs offer superior thermal conductivity than aluminum PCB.

The base layer is made of a copper substrate that offers high thermal conductivity and heat transfer.

Copper core PCBs use prepreg or another high thermal conductivity insulation to improve heat transfer.

Copper foil makes up the circuit layer, and these often range from 1 to 10 ounces.

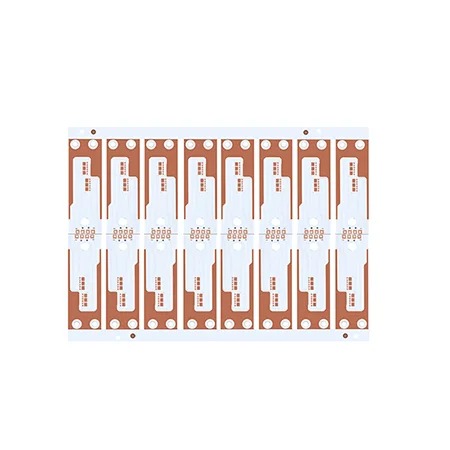

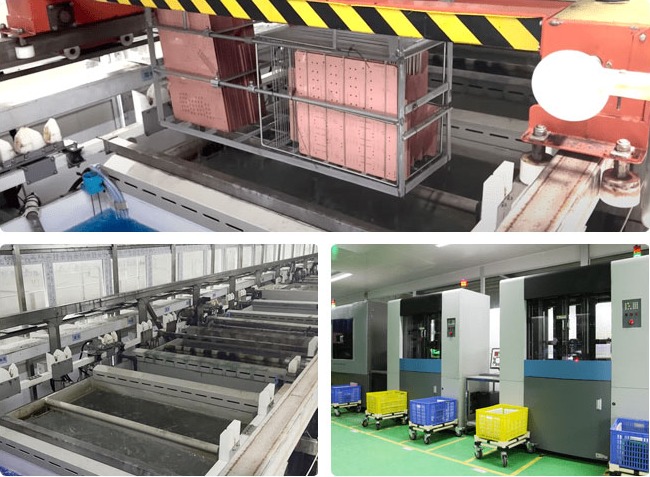

With 17 years of dedicated experience in MCPCB and a 3000-square-meter factory, we have served more than 1265+ clents, capable of handling prototype to mass production and assembly, catering to the diverse needs of our clients.

Of all the metal core PCB options, copper has the highest level of thermal conductivity. With higher conductivity, the heat transfer and dissipation are much stronger.

As an entirely natural material, copper is 100% recyclable. Using copper core boards can make your projects more environmentally friendly.

With higher heat dissipation, copper core PCBs are less likely to distort or corrode over time, making them more durable than fiberglass circuit boards.

It has more efficient heat dissipation than aluminum PCBs, which makes it an ideal choice for higher requirement of heat dissipation.

Copper core circuit boards are a type of metal core PCB that using copper substrate. With their layered design using a copper base, these PCBs offer superior thermal conductivity than aluminum PCB.

To meet diverse project requirements efficiently, to ensure the optimal performance and reliability of our Copper PCB, HaloSemi utilize top-grade materials and state-of-the-art equipment.

Count on us to deliver the best service to you.

Years of industry

M2/Month

Staffs, include 25+Engineers

Trade Country

Your Quote will be replied in 24Hours, from the email with the suffix “@Halosemi.com”.