1. What is an Aluminum PCB? A Comprehensive Overview

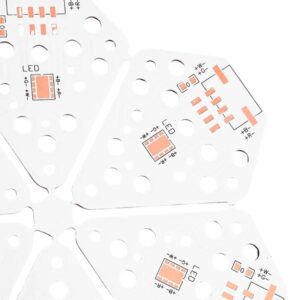

Aluminum PCBs, commonly known as Metal Core PCBs (MCPCBs), are a specialized type of printed circuit board featuring an aluminum base material instead of the traditional options like fiberglass or epoxy-based materials such as FR4. This unique metal base acts as an excellent heat sink, significantly improving heat dissipation from electronic components—a crucial feature in high-power LED designs. Structurally, Aluminum PCBs are formed of three main layers: a conductive copper foil for electrical operations, an insulating layer to ensure electrical isolation, and an aluminum substrate designed for thermal management. Their efficient and straightforward design is widely regarded as transformative, particularly in industries like automotive, aerospace, and LED lighting. The inherent ability of aluminum to endure high temperatures without distortion or degradation makes it an ideal platform for supporting LED chips, ensuring stability and optimal performance even under continuous use.

2. Heat Dissipation: Enabling Extended LED Longevity

Effective heat management is a decisive factor in the performance and durability of LEDs. Even though LEDs are energy-efficient, they generate significant heat during operation. If this heat isn’t dissipated effectively, it can lead to overheating, reduced light output, and premature component failure. Aluminum PCBs have become indispensable in addressing this challenge due to their excellent thermal conductivity. By rapidly transferring heat away from the LED chip, aluminum prevents overheating and ensures that the LED operates within its optimal temperature range. This not only boosts LED performance but also prolongs its lifespan, making Aluminum PCBs an essential choice for sustainable and reliable lighting technologies.

3. Exceptional Thermal Conductivity: A Core Advantage

Thermal conductivity—how well a material transfers heat—is a critical consideration in LED applications. Aluminum outperforms most conventional materials in this property, making it an ideal choice for Aluminum PCBs. Its superior thermal properties facilitate rapid heat dissipation from the LED chip, stabilizing temperatures and preventing potential issues like dimming or premature failures. Compared to traditional PCB materials, such as FR4—which has relatively low thermal conductivity—Aluminum PCBs demonstrate significantly better thermal performance, ensuring LEDs remain bright, efficient, and reliable over extended time periods.

4. Cost-Effectiveness: The Smart Investment for LED Manufacturing

Although Aluminum PCBs may initially appear more expensive than standard FR4 options, their broader advantages make them a wiser investment in the long run. Their superior thermal efficiency reduces risks of overheating and failure, resulting in longer-lasting LED products that require fewer replacements and minimal maintenance costs. Moreover, improved energy efficiency lowers electricity consumption for users, further reducing operational costs. For manufacturers, the increased reliability and performance of Aluminum PCB-based products enhance market competitiveness by delivering high-quality lamps that satisfy both business objectives and consumer expectations.

5. Selecting the Perfect Aluminum PCB for Your LED Design

Choosing the appropriate Aluminum PCB for your LED lamp design involves balancing several factors, including the LED system’s thermal requirements, lamp size constraints, and environmental conditions. For instance, high-powered LEDs used in outdoor applications like floodlights demand PCBs with exceptional thermal management capabilities to prevent overheating. Meanwhile, compact designs for applications like desk lamps may require PCBs that emphasize space efficiency without sacrificing thermal performance. Partnering with experienced PCB manufacturers is vital to developing tailored solutions that meet these specific needs. Customizing the right Aluminum PCB ensures optimal functionality and reliability for your LED lamp system.

6. Conclusion: Shaping the Future of LED Lighting with Aluminum PCBs

As demand grows for energy-efficient and high-performing lighting solutions, Aluminum PCBs will continue to take center stage in driving innovation within the LED industry. Their unmatched ability to manage heat efficiently, coupled with their robust durability and compact design benefits, places them far ahead of traditional PCB materials in meeting modern lighting requirements. As LED technology progresses, Aluminum PCBs will remain critical to creating cost-effective, sustainable, and long-lasting solutions. By integrating these advanced materials into lighting designs, manufacturers can develop products that are not only efficient but also environmentally conscious—a vital step forward in the evolution of illumination technologies.